Customer information

About us

TEH – tubular electric heaters are used to achieve different temperatures in appliances, rooms or temperature zones in different facilities, where this is necessary. This is achieved by appropriate selection of their power, configuration and their correct location in the place of use. The production technology of ELEKTROTERM VARNA is highly flexible, which allows the production of heaters with different types of pipes, in arbitrary shapes, in order to satisfy the most diverse requirements. The materials used (copper, stainless steel) to make the pipes are practically inactive with respect to oxygen, and the material used to fill the pipe has excellent heat conducting and dielectric parameters. They, as well as the production technology, guarantee a long life of the heater if correctly sized according to the working conditions. In this regard, the information submitted by the CLIENT regarding the specific operating conditions, as well as its specific requirements, will be of great benefit to the manufacturer.

INFORMATION NEEDED TO DESIGN HEATERS

In order to size a heater correctly, it is necessary to know several basic parameters determining the operating condition of the product: type of device in which it is installed, specific operating environment (water, air, oil, etc.) as well and the method of heat removal (cooling), operating temperature, and also requirements regarding the time to reach it.

Operating voltage V

Working power W

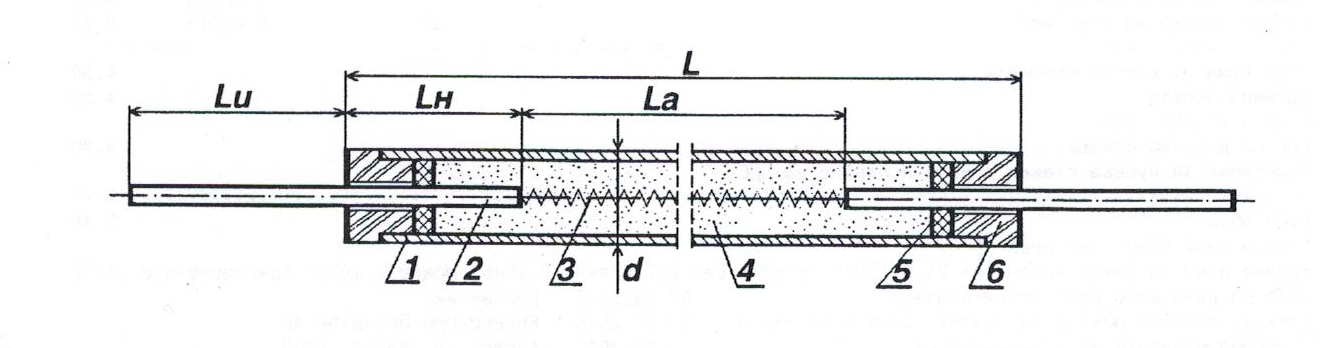

Dimensions of the heated zone and of the inactive part

Heater sample or detailed drawing with all required dimensions (including extended heater length)

Fasteners – type and dimensions

Commutation (type and number of electrical connections)

IN CASE OF SPECIAL REQUIREMENTS FROM THE CLIENT, THEY MUST BE EXPRESSLY MENTIONED IN THE BIDDING DOCUMENTS.

From the information below, you will have an overview of the limitations imposed by the manufacturing process and the materials used that heater designers need to be aware of.

Heaters operating in water environment

This group includes all heaters that have direct contact with fluids. It is characteristic of these heaters that they work at low temperatures (up to 120 degrees) and at a high degree of heat removal.

Heaters operating in an air (gas) medium

This group includes all heating elements that work in furnaces, ovens, air heaters and other similar equipment. Most of them operate at high temperatures (over 650 degrees) and poor cooling, therefore it is necessary to reduce the boundary values of the perimeter of “Surface load” in order to guarantee the operability of the heater for a long period of time. This is achieved by reducing the rated power of the heater, either by increasing the active length or possibly limiting with thermostats.

MATERIALS

TEHs are produced from the following types of tubes.

At an operating temperature of up to 300 degrees, copper 10×0.8mm and stainless steel pipes are used.

At temperatures above 450 degrees, stainless steel pipes.

The longest heaters reach a length of up to 5000mm with a section of φ6.5 φ8 φ9.5.

TEH BENDING

The shape of the heaters helps to make full use of its capabilities. It is necessary to know that the shape of the tubular heaters can be obtained from several bends, which alone or in combination can give a desired shape. Correctly constructed configuration is a guarantee for the proper functioning and longevity of the heater. It is very important for us that the CUSTOMER provides accurate information about the shape and dimensions of the heater.

TYPES OF ELECTRICAL CONNECTIONS

Electrical connections comply with standardized requirements and ensure high quality and operational reliability.

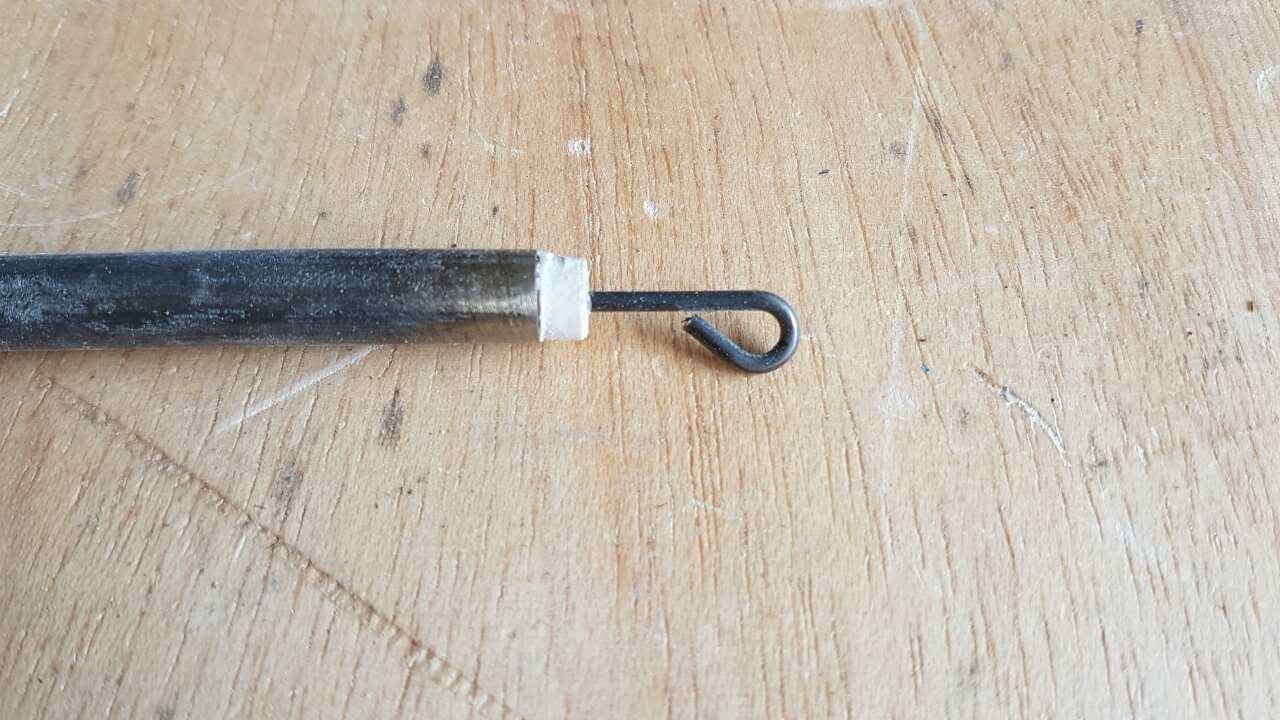

We have different types of plugs: single plug connection with three options straight, bent at 45 and 90 degrees, two plug connection with bent at 45 and 90 degrees, you can see the other types in the pictures.

We offer an option for an electrical connection without plugs with an O-shaped terminal bend.

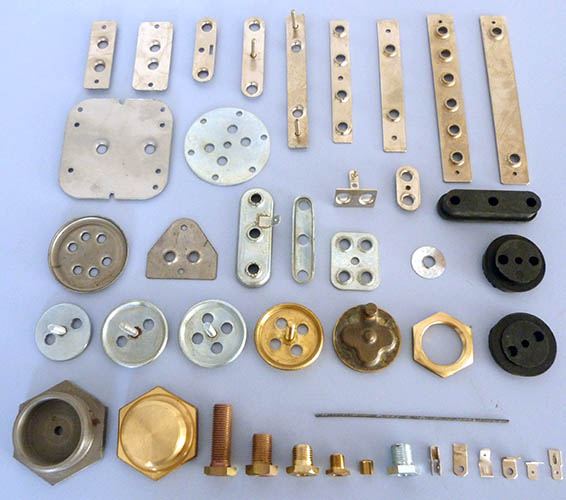

TEH FIXING

For the installation of a given tubular heater in an electrical appliance, when its technical parameters and shape are specified, the fastening element is important. The company has a certain range of fastening elements serving the production nomenclature, which is constantly updated. Due to the wide variety of elements used in world practice for sprinkling heaters, in agreement with the customer, it is possible to proceed to the manufacture of new designs.

Brass flanges and nipples are soldered with silver solder or tin. The stainless pipes are soldered with silver solder, and the copper ones depending on the application of the heater can also be soldered with tin.

The fasteners come in a variety of thicknesses, shapes and holes. After processing, they are nickel-plated or galvanized. According to the type of heater or according to the customer’s requirements, we can make stainless steel plates. Fastening to the heater is done by crimping the plate or nipple with press machines.

We make spirals with different cross-sections of the resistance wire from kanthal. Their application is in furnaces for higher temperatures. Besides spiral bending, Kantala can be bent into other shapes.